We specialize in cost engineering and value analysis of electronic and electromechanical assemblies.

Sourcing

Challenges:

- OEMs often unknowingly overpay for electronic and electromechanical subassemblies used within their final product.

- Commodity managers and buyers don’t have cost estimates and technical support to use during supplier negotiations.

- Commodity managers and buyers have a transactional relationship with suppliers due to a lack of visibility to the true “should cost” of their electronic / electromechanical spend.

- Commodity managers and buyers spend a large part of their workday addressing shortages of electronic components and “chasing parts” – limiting the time that they can focus on strategic sourcing activities.

How Senoia Engineering Solutions Can Help:

- Supplier Negotiations – Senoia Engineering Solutions can perform “deep-dive” analysis on your targeted electronics/electromechanical spend. We use our experience to develop “should cost” estimates for the piece cost and we provide support to your negotiations – driving more efficient, data-driven discussions with your suppliers.

- Analysis of Tooling Costs– We can provide analysis and guidance in evaluating tooling charges from your suppliers and differentiating between these charges and capital equipment that the supplier should pay for.

- Analysis of Engineering Design & Test Charges – Senoia Engineering Solutions can provide analysis, consultation, feedback of your suppliers’ product development and product testing charges.

- Alternate Component Strategies – Using our extensive experience in electronics design, Senoia Engineering Solutions can analyze your products and identify alternate electronic components that can be used. We can then develop a component substitution strategy to mitigate component shortage issues.

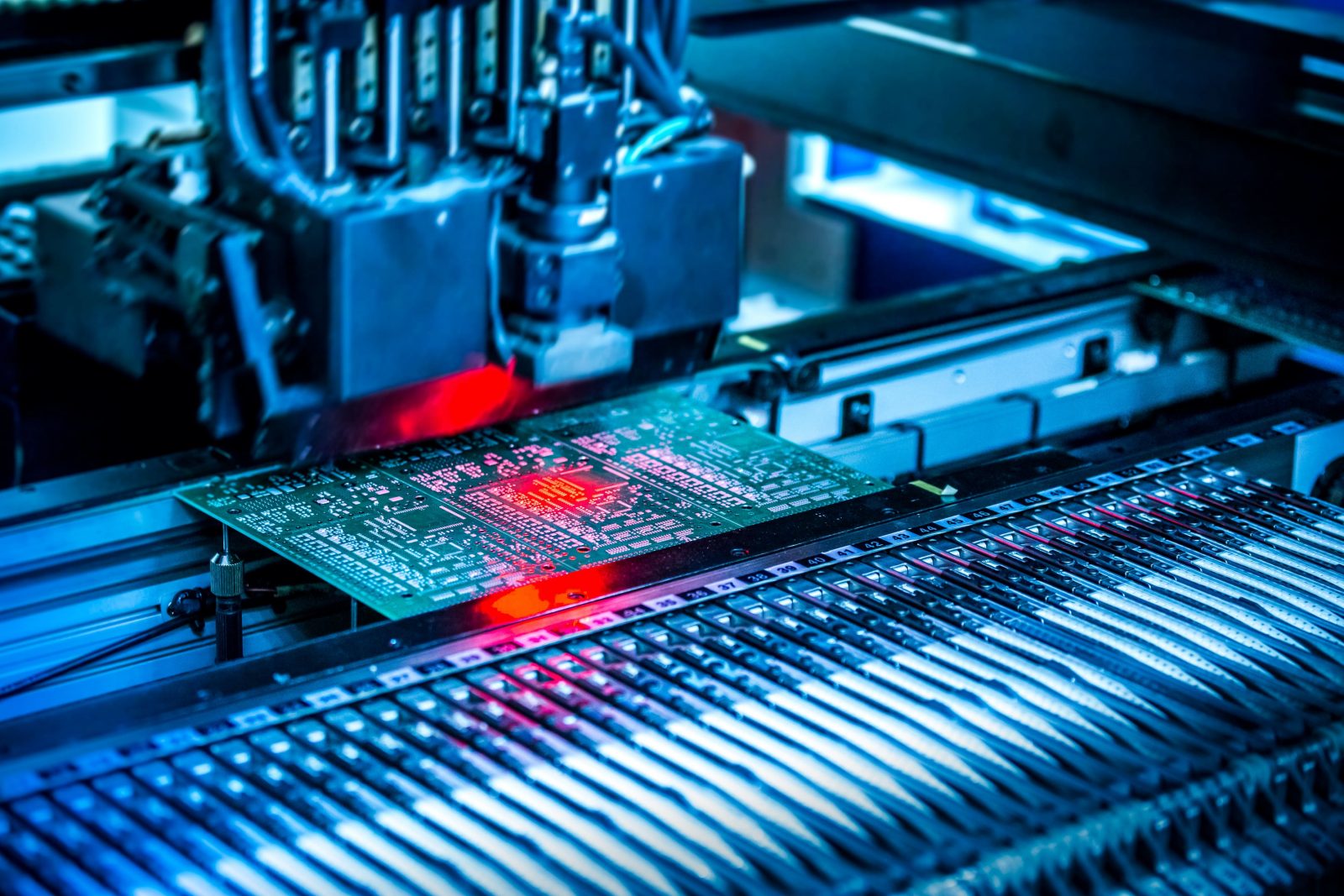

Design

Challenges:

- Design engineers are challenged to meet a target cost, but don’t have a timely way to measure their design against this goal.

- OEMs struggle to control “cost creep” as a new design progresses from concept to prototype to volume production.

- Assessment of competitors’ designs frequently focuses on physical design attributes but doesn’t provide insight into cost advantages /disadvantages.

How Senoia Engineering Solutions Can Help:

- Establishing Cost Targets – Drawing from our vast experience in the electronics industry, Senoia Engineering Solutions can analyze your design and determine an appropriate target cost based upon current technology and industry standards.

- Identifying Design-Related Savings Opportunities – We can generate cost estimates of various design approaches to enable better trade-off decisions and to ensure a cost optimized design.

- Competitive Teardown Analysis and Assessment – Senoia Engineering Solutions can provide a side-by-side analysis of your design compared to your competitors, thereby identifying appropriate actions to make your design more competitive.

Design

Challenges:

- Design engineers are challenged to meet a target cost, but don’t have a timely way to measure their design against this goal.

- OEMs struggle to control “cost creep” as a new design progresses from concept to prototype to volume production.

- Assessment of competitors’ designs frequently focuses on physical design attributes but doesn’t provide insight into cost advantages /disadvantages.

How Senoia Engineering Solutions Can Help:

- Establishing Cost Targets – Drawing from our vast experience in the electronics industry, Senoia Engineering Solutions can analyze your design and determine an appropriate target cost based upon current technology and industry standards.

- Identifying Design-Related Savings Opportunities – We can generate cost estimates of various design approaches to enable better trade-of decisions and to ensure a cost optimized design.

- Competitive Teardown Analysis and Assessment – Senoia Engineering Solutions can provide a side-by-side analysis of your design compared to your competitors, thereby identifying appropriate actions to make your design more competitive.

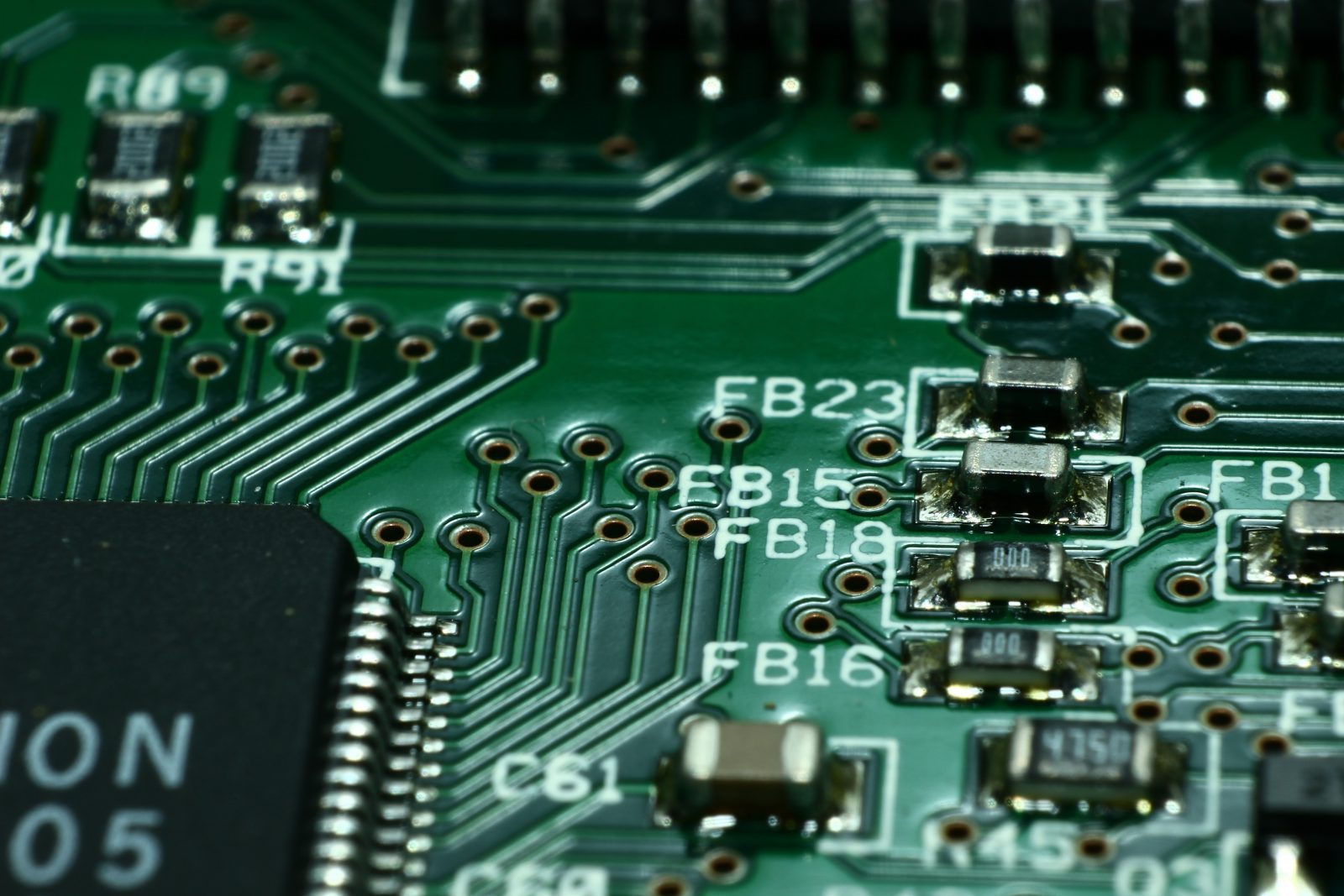

Manufacturing

Challenges:

- The launch of a new electronic/electromechanical product frequently experiences manufacturability issues and quality problems

How Senoia Engineering Solutions Can Help:

- Design For Manufacturability / Test – With over 35 years of experience in the industry, Senoia Engineering Solutions can provide a “second set of eyes” to evaluate a new design and identify manufacturing, testing, and quality issues BEFORE volume production begins.

Cost Engineering

Challenges:

- Companies don’t have a formal in-house Cost Engineering function.

- If they do, they may lack the expertise in the electronic and/or electromechanical assemblies.

How Senoia Engineering Solutions Can Help:

- Organizational Knowledge – Senoia Engineering Solutions can help you lay the foundation for a cost engineering discipline within your organization, implement a cost engineering department, and recruit personnel who possess the appropriate skill sets.

- Expertise – With over 35 years of vast experience in the electronics industry, Senoia Engineering Solutions can provide support and training in challenging cost issues related to electronics and/or electromechanical technology.

Cost Engineering

Challenges:

- Companies don’t have a formal in-house Cost Engineering function.

- If they do, they may lack the expertise in the electronic and/or electromechanical assemblies.

How Senoia Engineering Solutions Can Help:

- Organizational Knowledge – Senoia Engineering Solutions can help you lay the foundation for a cost engineering discipline within your organization, implement a cost engineering department, and recruit personnel who possess the appropriate skill sets.

- Expertise – With over 35 years of vast experience in the electronics industry, Senoia Engineering Solutions can provide support and training in challenging cost issues related to electronics and/or electromechanical technology.